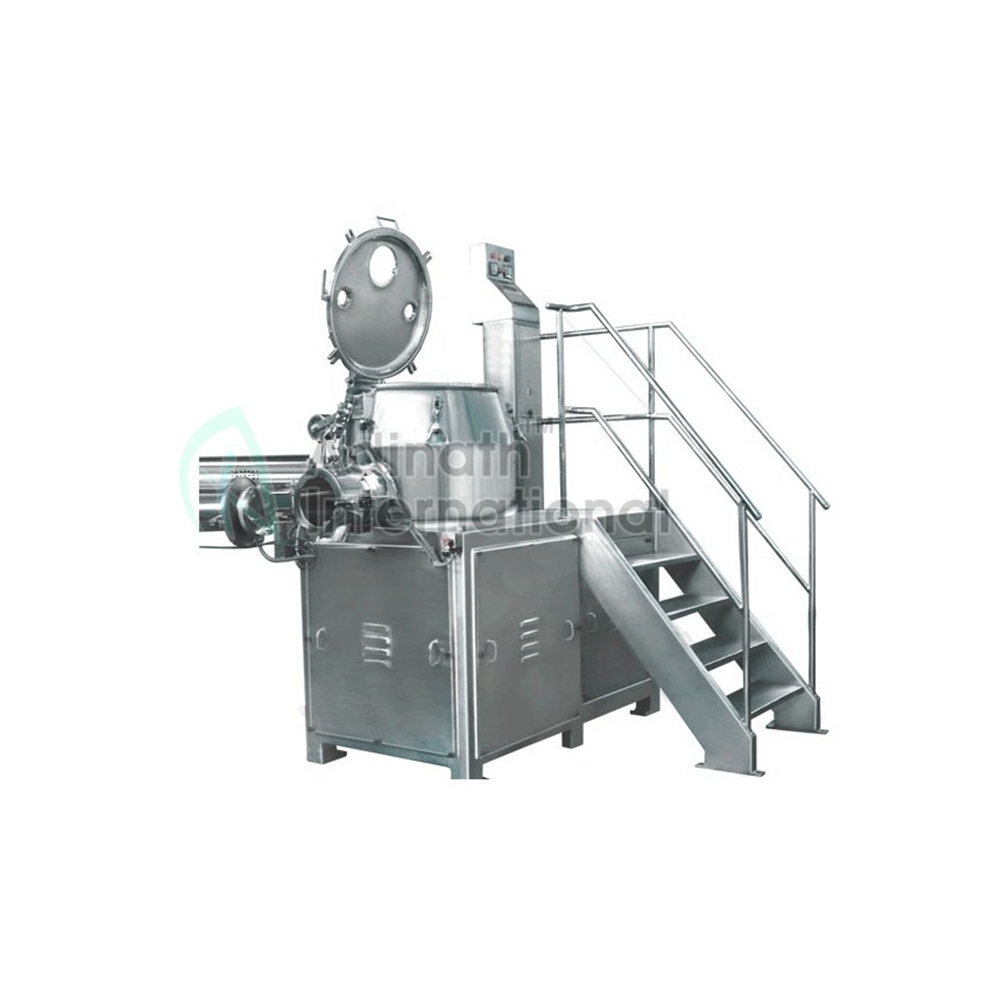

Rapid Mixer Granulator

Rapid Mixer Granulator is developed for mixing of ingredients as well as wet granulation required for tablet/ capsule manufacturing process. This is achieved by reduced processing time, more homogeneous mixing, and uniformity of granule size and above all maintaining improved hygiene compliant to cGMP norms.

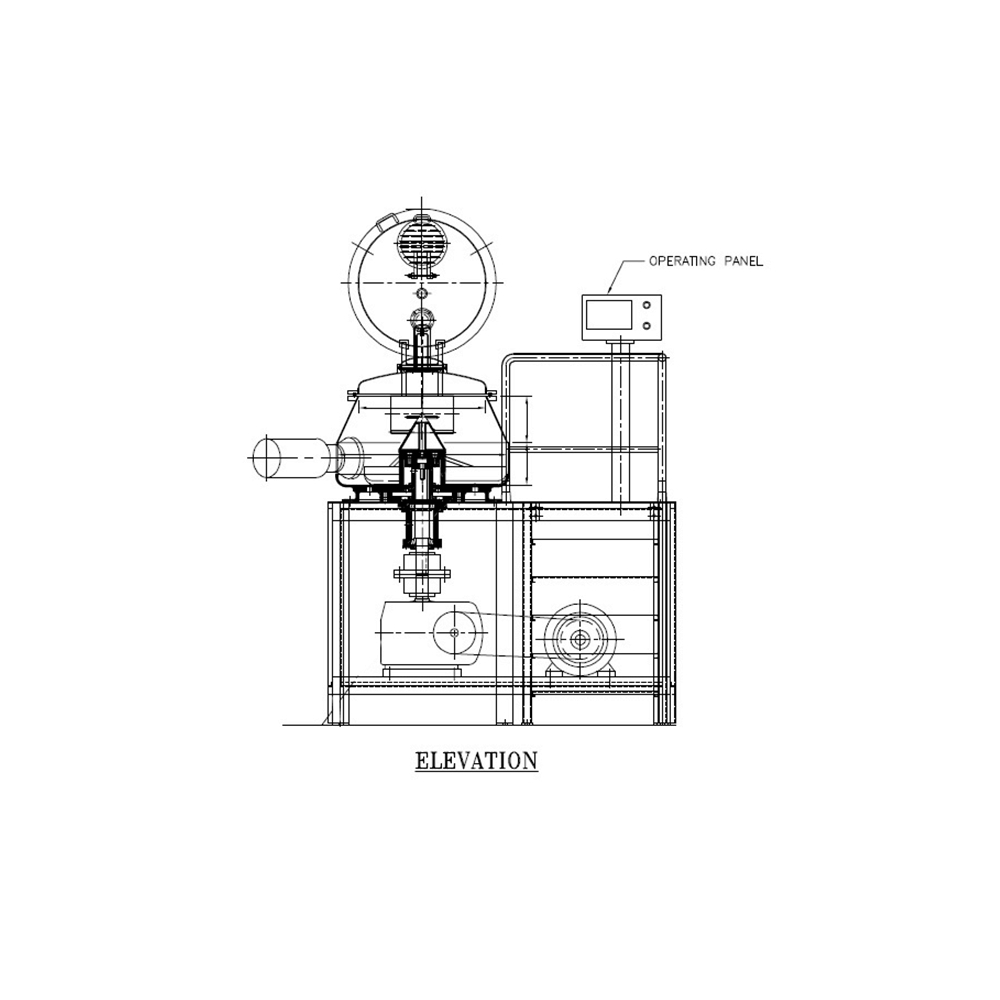

Mixing Bowl:

The main drive, shaft seal is on the top of tube and thus well above the normal powder level. The Shaft seal is provided with automatic air purge. The seal housing and drive shaft may be flushed with cleaning water, which is then drained away from the machine through built discharge port.

The multi-bladed impeller is fitted close to the base of the mixing bowl whereas the chopper is mounted on the wall of the mixing bowl. Both the impeller & the chopper have dual-speed options for gently distributing the binder solution as it is added and creating the vortex of the material being mixed.

Granulator:

The granulator rotates at two speeds 1500 or 3000 RPM. The granulator head is of highly polished stainless steel and is easily removable for cleaning.

The Granulator Shaft where it enters the bowl incorporates AIR PURGED SEAL.

The motor is provided with a removable stainless steel covers to meet cGMP norms.

Online Co- Mill

Side Discharge Valve:

A cover with removable silicone rubber seal gives unrestricted access into the chute for easy cleaning.

A safety lock in the form of a limit switch is provided at the discharge port to prevent the valve or the motors to start during the cleaning operation.

The pneumatic cylinder is covered with stainless steel shroud to meet cGMP standard.

Salient Features of Rapid Mixer Granulator:

A cover with removable silicon rubber seal gives unrestricted access into the chute for easy cleaning

A safety lock in the form of a limit switch is provided at the discharge port to prevent the valve or the motor to start during the cleaning operation.

The pneumatic cylinder is covered by a stainless steel shroud to meet cGMP standard

| Technical Specification | Lab Models | Pilot Models | Production Models | ||||||||||

| AI-RMGM 3 | AI-RMGM 5 | AI-RMGM 10 | AI-RMGM 15 | AI-RMGM 25 | AI-RMGM 75 | AI-RMGM 100 | AI-RMGM 150 | AI-RMGM 250 | AI-RMGM 400 | AI-RMGM 600 | AI-RMGM 800 | AI-RMGM 1200 | |

| Working Capacity in Liters | 3 | 5 | 10 | 15 | 25 | 75 | 100 | 150 | 250 | 400 | 600 | 800 | 1200 |

| Working Capacity in Kilograms | 0.5 to 1.2 | 1 to 2 | 2 to 4 | 4 to 6 | 8 to 10 | 20 to 30 | 25 to 40 | 40 to 60 | 70 to 100 | 100 to 160 | 150 to 240 | 180 to 320 | 280 to 480 |

| Main Motor 750/1440 RPM | 2/3 | 2/3 | 2/3 | 3/5 | 3/5 | 3/5 | 5/7.5 | 10/12.5 | 25/30 | 30/40 | 50/100 | 60/75 | 80/100 |

| Chopper Motor 1440/2880 RPM | 0.5/1 | 0.5/1 | 0.5/1 | 0.5/1 | 0.75/1.5 | 1.5/3 | 1.5/3 | 2/3 | 3/5 | 5/7.5 | 5/7.5 | 5/7.5 | 10/15 |

| Gear Box Size | NMRV P075 | NMRV P075 | NMRV P075 | NMRV P075 | NMRV P075 | W110 | V500 | V600 | V700 | V800 | V1000 | V1200 | V1200 |